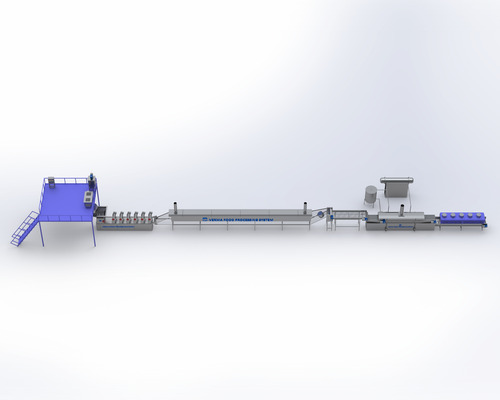

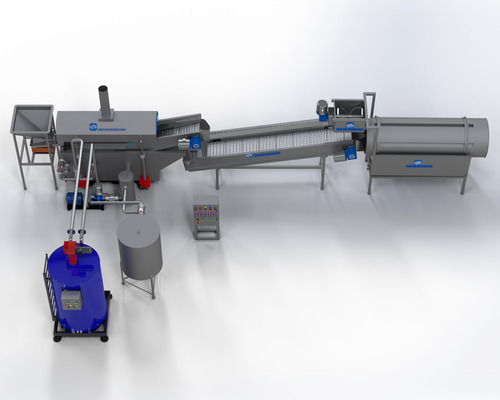

Automatic Instant Noodles Plant

Product Details:

- Type Automatic Instant Noodles Plant

- Material SS

- Computerized No

- Automatic Grade Automatic

- Warranty 1 year

- Click to View more

Automatic Instant Noodles Plant Price And Quantity

- 1 Unit

- 6500000 INR/Unit

Automatic Instant Noodles Plant Product Specifications

- SS

- Automatic

- 1 year

- Automatic Instant Noodles Plant

- No

Automatic Instant Noodles Plant Trade Information

- 10 Unit Per Month

- 10 Week

- Contact us for information regarding our sample policy

- All India

Product Description

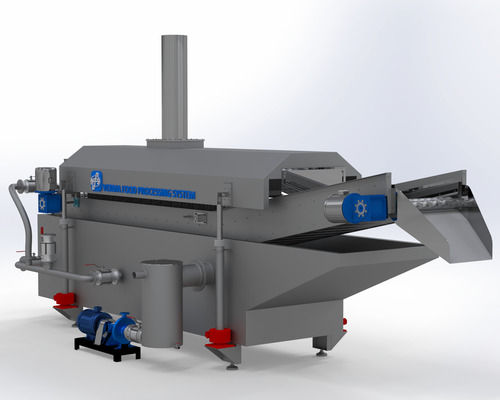

We are pleasure to introduce to our self Verma Food Processing System since 2008. We are presently making a large range of food processing machines. We made machines as latest technology helpful in save energy and time. we are manufacture of all type food processing as complete line of Kurkure, fryums, Popcorn Line, Namkeen, Puff Online and Potato Chips Line in semi automatic and fully automatic and related all equipment of Food industry. We are committed to provide our best and latest services & machines in food industry. Our machines and new technologies helpful for your industry more growing and help for achieve of your goal so if your requirement of any food processing plants & other food equipments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Frying System' category

GST : 09BRUPK0170M1Z7

|

|

VERMA FOOD PROCESSING SYSTEM

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |